Objective sampling

No operator influence means objective sampling without any human influence on the sampling procedure. Additionally, the collected samples represent the daily production of quality correctly. ROFIT 200 enables higher statistical validity of the sampling procedure. The random sampling of fiber bundles out of the filling chamber guarantees for representative average whiteness measurements.

Time saving

The automatic sampling procedure leaves the operator free capacities for other tasks.

Test method

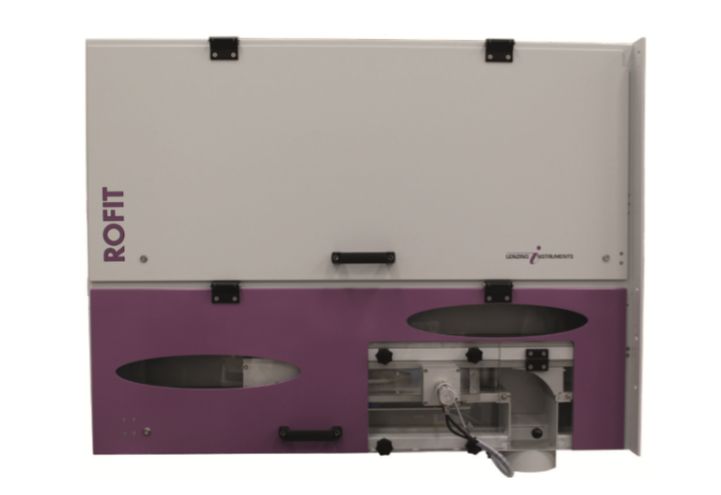

ROFIT 200 enables automatic and controlled sampling of staple fibers from the filling chamber of the baling press. In the filling chamber above the baling press, a horizontally moving grabber grabs fibers of a defined sample size. A sample is collected at a frequence of up to six times per minute. The collected fiber sample is released via a sample outlet. Further handling by the customer could mean presenting a plastic bag to the fiber sampling chamber for proper packaging. Alternatively, the collected samples can be dropped into a fall tube down to the baling press level. By means of a three filter measuring unit, ROFIT 200 also features semicontinuous measurement of whiteness, yellowness and fluorescence according to Berger and TAPPI. The output signals can be used for optional automatic control of the bleaching section.